ABOUT UNIMANIX

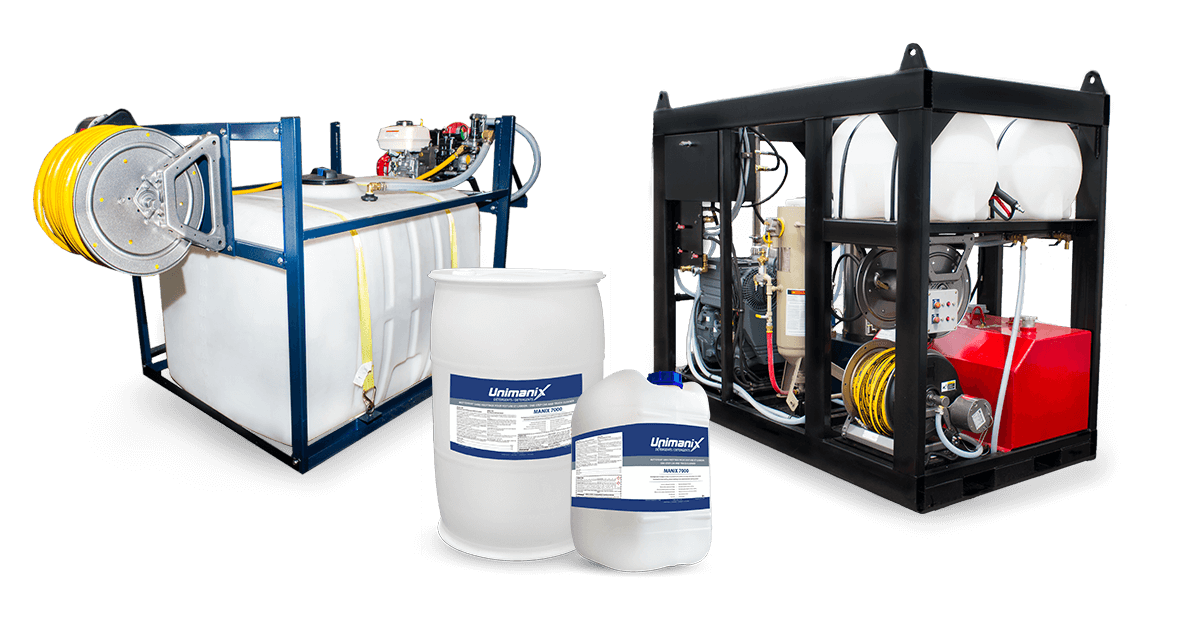

Unimanix is a a leading manufacturer of industrial grade, high-pressure washers and industrial washing systems. Our knowledgeable staff and growing network of dealers will assist in helping you pick the best industrial pressure washer and accessories for your cleaning job.

With over 25 years of expertise in manufacturing pressure washer systems, Unimanix has firmly established itself as a leader in reliable industrial and commercial pressure washers. Today, Unimanix is one of the largest manufacturers of industrial-grade pressure washers and high-pressure washer systems in Canada serving a diverse clientele. Unimanix can design, install and maintain custom pressure washer systems for light, medium, and heavy-duty usage and for any application. We also offer cleaning solutions for food and non-food manufacturing companies who require parts cleaning using our industrial washing systems.

PRESSURE WASHER MAINTENANCE SERVICES

We firmly believe in providing the best pressure washer maintenance and repair services for our customers. Our continued growth as a leading manufacturer in industrial-grade pressure washers comes from our dedicated service team and growing dealership throughout Canada. Our continued growth as a leading manufacturer in industrial-grade pressure washers comes from our dedicated service team and growing dealership throughout Canada.

Because of our 25 years of expertise, we also repair and service related brands of high-pressure washers and automatic parts washers. Unimanix also maintains and replenishes the highest stock levels of pressure washer parts ensuring you get immediate after-sale service for replacement parts and accessories. We provide different after-sales services based on your need, from preventative maintenance, winterising to changing a specific part - you can count on Unimanix for prompt service and parts when you need it. To learn more about our Pressure Washer Maintenance Service, please click here to visit the Services page.

INNOVATIONS IN PRESSURE WASHER EQUIPMENT

UNIMANIX continually invests in research and development to offer the latest in pressure washer systems that meets the demands of any cleaning application for any industry.

Every year new pressure washer models are developed at Unimanix. And since 1993, we have improved and introduced new 100% electric pressure washer solutions, dry steam generators, jet wash solutions, surface preparation solutions and mobile pressure washer systems.

We are proud to claim that we offer the most comprehensive list of commercial and industrial pressure washer solutions in Canada.

CUSTOM DESIGN SOLUTIONS

In addition to our standard durable pressure washers, Unimanix provides custom solutions to meet the stresses of tough washing applications in the most demanding environments. Our industrial grade pressure washers are completely customizable making these the number one choice for commercial fleets, municipalities, transportation, military assets, heavy-duty equipment, off-road, construction and mining equipment.

You can trust Unimanix to custom design your pressure washer system that meets environmental conditions, vehicle needs, water restrictions, space allotment and budgetary concerns. Contact your sales representative, today !

BLOG

How Pressure Washing Can Help Prevent the Spread of The Flu

We understand that you need to protect your customers and employees from the flu and other viral diseases. Ongoing preventative maintenance and pressure cleaning are two excellent ways to protect your employees and keep your operations running smoothly. How Pressure Washing Can Help Prevent the Spread of The Flu Read more

Viandes Dunham reduced their water consumption by 25%

Discover how Viandes Dunham reduced their water consumption by 25% with a Unimanix pressure washers installation. Viandes Dunham reduced their water consumption by 25% Read more

5 safety tips before using a pressure washer

Here are five basic safety tips for any type of pressure washer.